Performance monitoring and predictive diagnostics are critical elements in the management of process plant and systems today. CVS is an expert in the planning and performing of valve maintenance requirements.

CVS' valve maintenance offering is scalable, making it equally applicable no matter what size of plant, be it on or offshore.

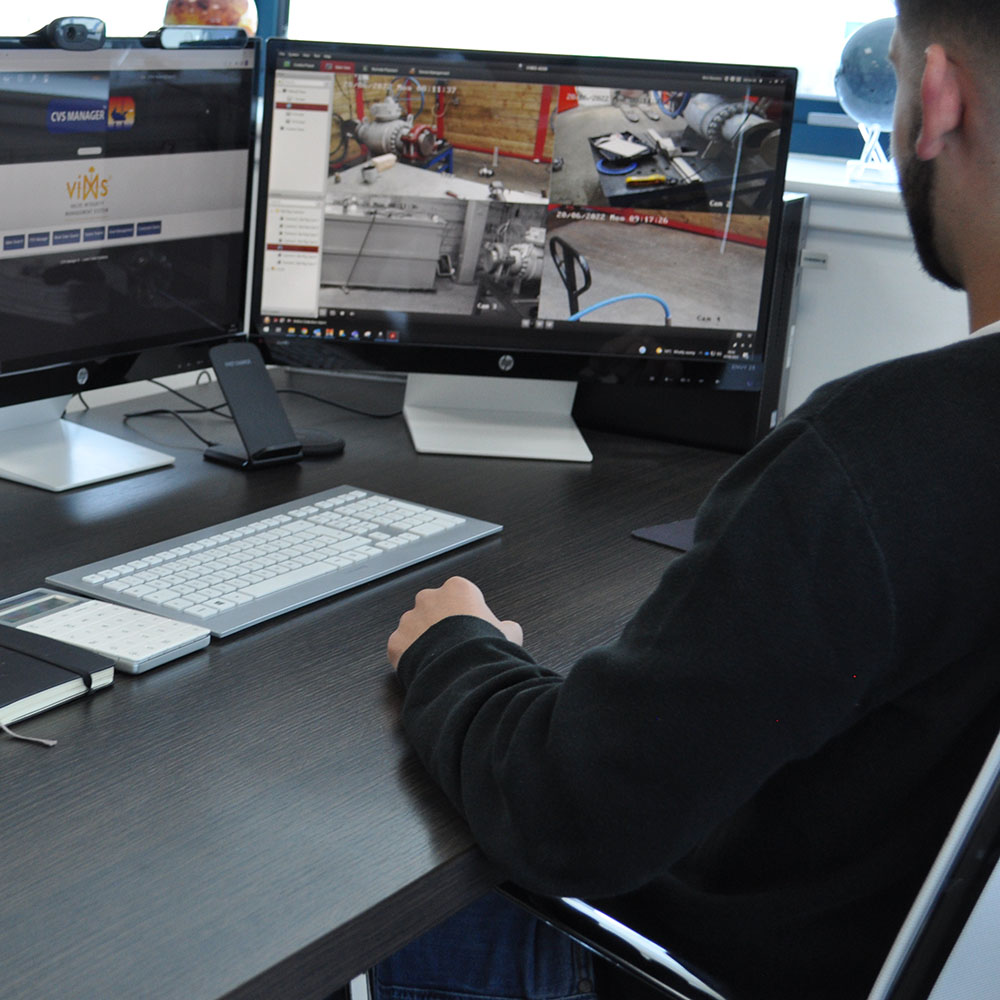

Witness testing can also be carried out in person or by using live web feeds to obtain test results through CVS Manager™ either on-site or in CVS' Aberdeen workshop.

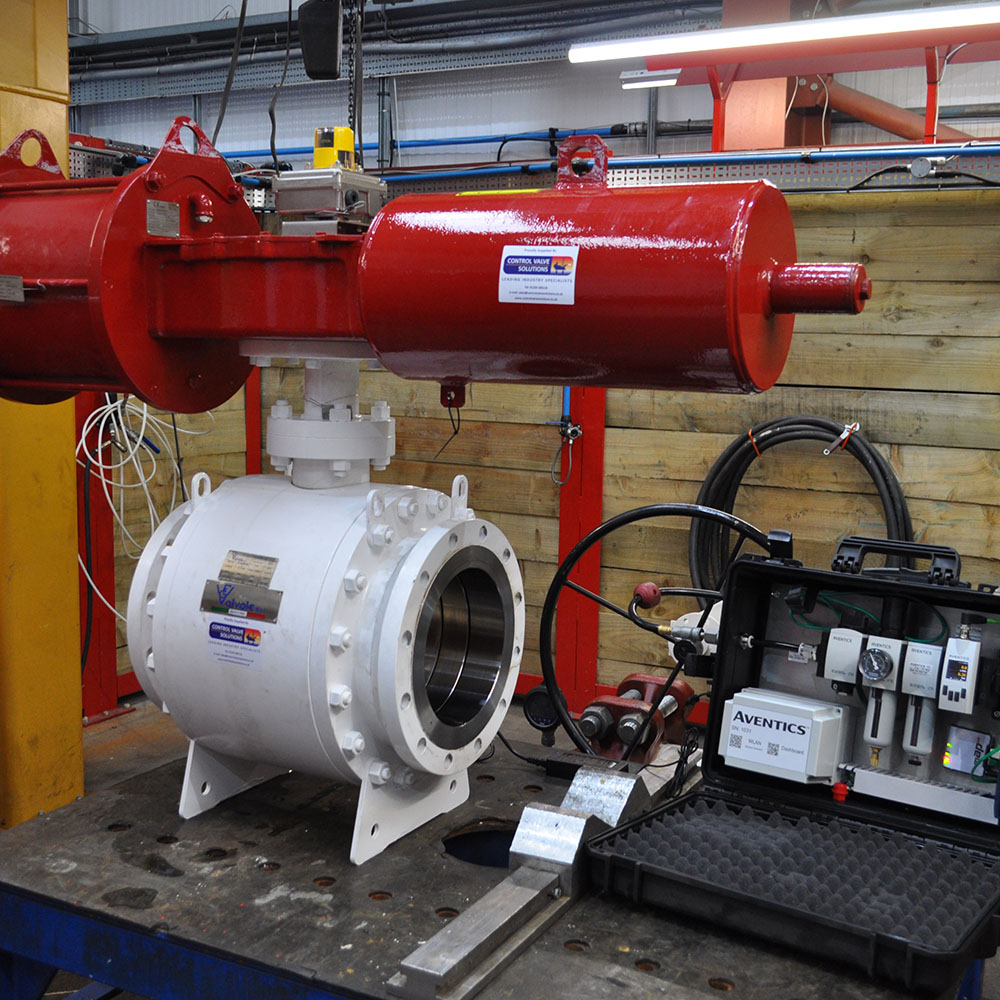

Comprehensive valve testing is performed in-house at CVS' purpose-built workshop and test facility, with 5 test bays, testing up to 22,500psi. Specialising in fine-tuning control and actuated valve instrumentation, enabling instrumentation enhancement based on the most appropriate and cost-effective options available to CVS as an independent provider.

Control valve performance monitoring is a vital component in the management of today's process plants and systems. CVS can now reliably forecast future failures for its clients due to groundbreaking technology. This service is invaluable since outages for overhauls can be scheduled at the most suitable date to minimise downtime.

Optimisation of valves, such as seawater ring main, anti-surge valves, and hydro cyclone valves, ensures the client's production efficiency and further reduces unplanned downtime. Instrumentation can be upgraded based on the most relevant and cost-effective product solutions open to CVS as an independent provider.

Valve performance tuning is a vital component in the management of today's process plants and systems. CVS can push high performing valves to their limits by using latest software to ensure the reaction times required by the client are met, whilst having the high accuracy required when it comes to controllability.

Free 24-hour Helpline: call our team today on

01224 583116